Laboratory for material

synthesis and crystal growth

consists of several crystal growth techniques such as Czochralski,

Bridgman or floating zone, thin film technology methods (thermal

evaporation, spattering, laser ablation), sol-gel technology, sintering,

etc. Here we will show only two crystal growth techniques.

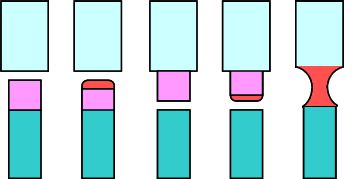

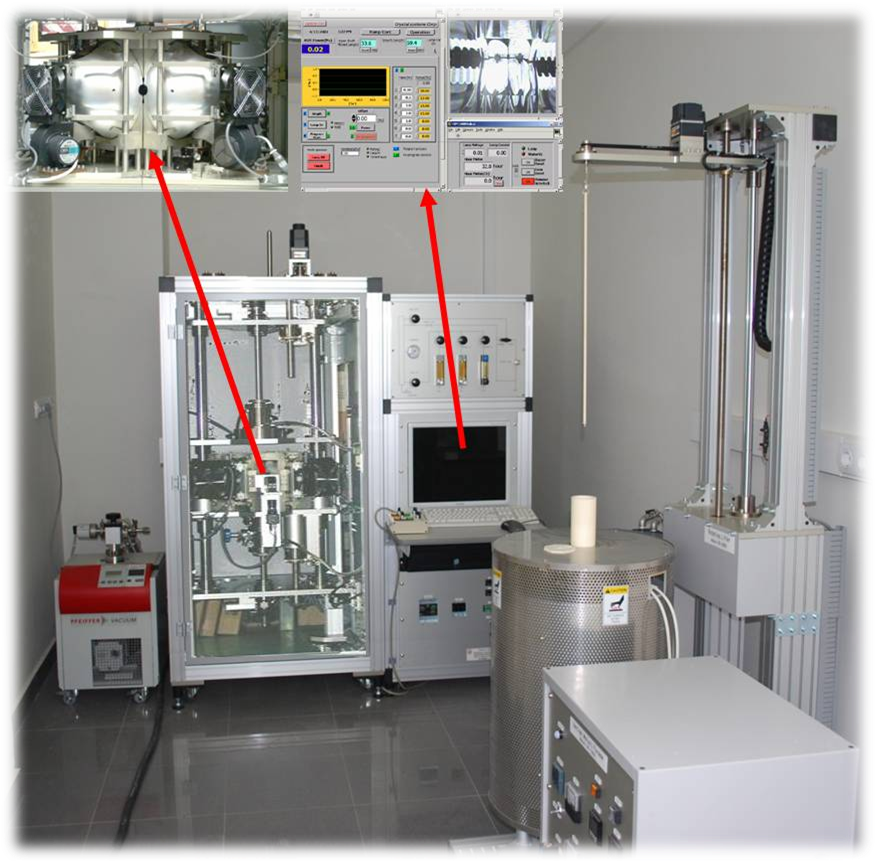

Crystal growth using floating zone technique: Four

Mirror Lamp Image Furnace.

The floating zone technique is a powerful

tool for the fabrication of high quality single crystals as well as for

the purification of materials. A new four mirror optical floating zone

furnace FZ-T-1000-H-HR-I-VPO-PC (Crystal System Co.) consists of

four ellipsoidal mirrors made of Pyrex glass coated with highly

reflective aluminum. The mirrors are air-cooled in order to prevent

moisture condensation on the ellipsoidal surfaces. The principle of this

technique is that radiation from the Halogen lamps is reflected and

focused by the mirrors onto the bar sample to form a molten zone at the

tip of the feed rod. Then the molten (floating) zone is translated along

the sample length by moving the mirror stage with respect to the sample.

The crystal is grown on the solidifying end of the floating zone. In

addition, a rotation movement of the rod improves the microstructural

homogeneity during directional solidification.

In the crucibleless floating zone technique the molten zone is kept together by capillary forces. The optical heating is the optimal way to bring a narrow zone of the sample to melting. In FZ-T-1000-H-HR-I-VPO-PC optical furnace the maximum operating temperature is 2200°C in atmosphere (air, nitrogen, oxygen, argon, etc) within the pressure range from 5x10-5 up to 10 bars. Crystals can be obtained up to 150 mm in length and 10 mm in diameter, with a growing rate of 0.05-27 mm/h and a 5-60 rpm rotating rate.

Four mirror optical furnace model FZ-T-1000-H-HR-I-VPO-PC (Crystal

System Co.)

with vertical molysili furnace model VF1800 (right).

Advantages of the four mirror floating zone furnace:

1) Stable

molten zone - Using high quality four glass mirrors and aluminum

frame, a stable molten zone can be achieved;

2) Small size -

Mirror stage moving system can diminish the scale of the furnace, so

that crystals as long as150 mm can be grown;

3) Remote

monitor and remote control system - Connect a PC to LAN system,

monitoring and controlling of the furnace can be done from anywhere in

the world;

4) PC control -

All the parameters for growing single crystals can be set and

controlled by the personal computer;

5) High

quality glass mirror - Suitable for a long-term use, and optimal

conditions are easily maintained. The surface is easy to clean, no

damage occurs;

6) Variety of halogen

lamps - The most suitable lamp can be selected from various power

lamps (150W, 300W, 500W, 1,000W and 1,500W lamp are available);

7) Monitoring by the CCD

camera - High quality color CCD camera and monitor can give real

time control of the growth;

8) Phase research by the

slow cooling float zone method - Stable molten zone by the four

mirror system can give the phase relation using the slow cooling float

zone method.

|

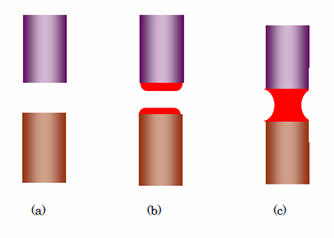

The growth of

incongruently melting or peritectic compounds |

Growth of congruently melting

compounds |

|

|

1) First stage: Set

the solvent zone chip on the top of the seed rod. A small amount

of starch paste can be used to fix it. The starch will be burnt

off as the temperature increases, and a small amount of smoke

will appear. |

1) At the initial

stage of the heating, both the feed and seed rod are set apart

by a distance of a few mm; |

Advantages of Floating zone in comparison

with the Czochralski method:

1) High purity crystals can be grown without contamination from the

crucible;

2) Can be applied to grow oxide, metal and other materials;

3) Can grow single crystals of incongruently melting materials;

4) Low cost of the crystals growth;

5) Can be applied in phase research by the slow cooling float zone

method.

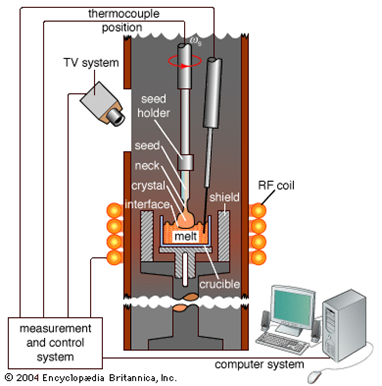

Crystal growth by the Czochralski method

|

The

Czochralski process is a method of crystal growth used to obtain

single crystals of many semiconductors (e.g. silicon, germanium

and gallium arsenide), optical materials (e.g. ruby, sapphire,

YAG, Bi12GeO20), metals (e.g. palladium, platinum, silver,

gold), salts and some hand made, (or "lab") gemstones. |

|

Occurrence of unwanted instabilities in

the melt can be avoided by investigating and visualizing the temperature

and velocity fields during the crystal growth process.

The process is named after Polish scientist Jan Czochralski, who

discovered the method in 1916, while investigating the crystallization

rates of metals.

Czochralski crystal growth system (Metals Research Co). Crystal ingot is Bi12GeO20.

Single crystals of several semiconductors

and optical materials obtained in our laboratory using the Czochralski,

Bridgman and floating zone techniques.

Center

for Solid State and New Materials :: Facilities

:: Laboratory for

material synthesis and crystal growth::

print